ENVIRONMENTAL REPORT

LABORATORY DETAILS

|

Lab Name |

Elisra - Environmental Test Laboratory |

|

Address |

48, Mivtza Kadesh St. Bene Beraq, 51203 Israel |

|

Tel. |

972-3-6175266, 972-3-5703708 |

|

Fax. |

972-3-6175866 |

|

|

dovc@elisra.com |

CUSTOMER DETAILS

| Customer Name | KENSUN |

DOCUMENT CONTROLThis document is a controlled document. It is your responsibility to ensure that you have the appropriate version of this document. This document is not subject to version control when printed. This document was developed using version 2.01 of the iDDE-2000/etr editing environment developed and supported by the corporate Software Engineering Department of the Quality Management Division. The format and contents of this document is in accordance with those provided by version 2.01 of the iDDE-2000/etr environment.

DOCUMENT HISTORYThe following table records information regarding released editions of this document and briefly describes their file location,purpose and changes made to them.

| Edition Id | Release Date | Responsible Author | File Reference, Purpose and Description of Changes |

| --- | 20/5/2007 | Guy Barkay | File Reference: REPORTS\kneson \kensun-1704.doc Purpose: Changes: |

DOCUMENT APPROVALSThis edition has been approved by:

| Name | Title | Signature | Date | |

| Author | Guy Barkay | Test Engineer |  |

May 20, 2007 |

| Approved | Dov Carmeli | Lab Manager |  |

May 20, 2007 |

DISTRIBUTION LIST

OPEN ISSUESThis part of the document control section is used to record and track open issues and/or unresolved questions.As the developmentof this document proceeds, these issues and questions should be resolved and then removed from the list.

| No. | Subject/Section | Description |

| 1. | ||

| 2. |

INTRODUCTION1.1. PURPOSE

The purpose of this document is to verify that the HID CONVERSION KIT meet all requirements as per the applicable documents.

1.2. SCOPE

The scope of this Environmental Test Report includes the environmental test results as specified by the customer and by the related resources.

1.3. GLOSSARY

| Abbreviation / Acronym / Term | Explanation / Description |

| iDDE | Integrated Document Development Environment |

| ID | IDentifier |

| NA | Not Applicable |

| TBD | To Be Defined |

| ETR | Environmental Test Report |

| ETS | European Telecommunication Standard |

| IEC | International Electronic Community |

| NC | Not Controlled |

| UUT | Unit Under Test |

1.4. APPLICABLE DOCUMENTS

This section contains a list of resources (e.g., documents, files, tools) referenced by or related to this document. All documents' revisions are the latest known on the date of the contract signing.

IEC-68

. BMW GROUP ELECTRICAL/ELECTRONIC ASSEMBLIES IN MOTOR VEHICLES GENERAL INFORMATION. GS 95003-1 MARCH/2000. SUPERSEDESRES 62.60013 PART 1, ISSUE 06.97. Elisra

1.5. EXECUTIVE SUMMARY

The following table summarizes the tests that have been performed in Elisra - Environmental Test Laboratory.

KENSUN performed the functional tests and they are his sole responsibility

| No. | Test Name | Pass/Fail |

| 1. | Low Temperature Test | Pass |

| 2. | High Temperature Test | Pass |

| 3. | Random Vibration Test | Pass |

Statement Of Compliance with test requirements.

We, Elisra - Environmental Test Laboratory, declare under our sole responsibility that the HID CONVERSION KIT were tested to comply with the requirements of the applicable environmental test specification.

LOW TEMPERATURE TESTUNIT UNDER TEST OVERVIEW

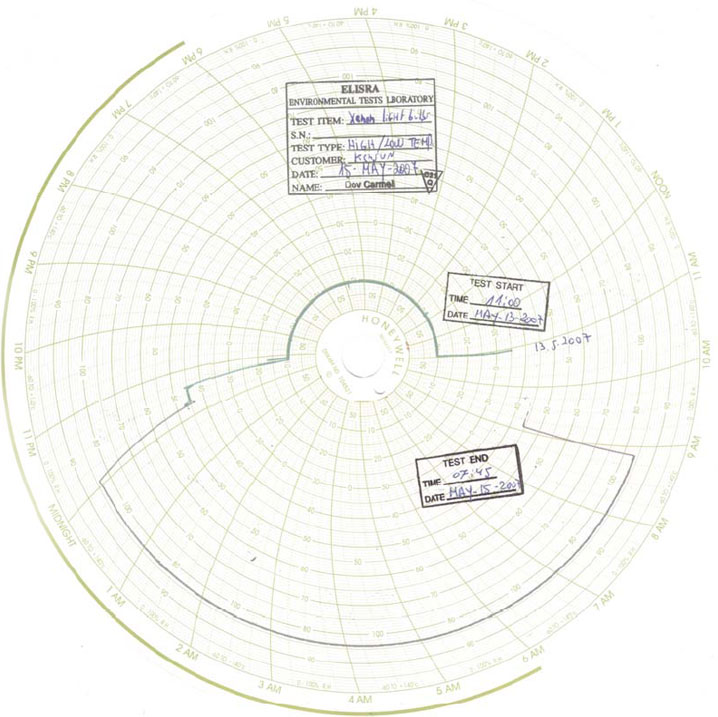

| Test Date | 13-14/5/07 |

| Customer Representative | Shmuel Etinger |

| Customer | KENSUN |

| Unit Name | HID CONVERSION KIT INCLUDES: H01 ELECTRONIC BALLAST 0902 ELECTRONIC BALLAST XENON LIGHTBULB |

| Item Quantity | 6 |

TECHNICAL SOURCE

. IEC-68-1 Test A : Cold.

TEST INSTRUMENTATION - TEMPERATURE CHAMBER

| No. | Manufacturer / Model | Calibration Expired Date |

| 1. | THERMOTRON Model F-35 | 31/10/2007 |

TEST PROCEDURE

EXCLUSIONS FROM THE TEST METHOD

Not applicable

LOW TEMPERATURE TEST PROCEDURE DESCRIPTION

| Period | 16 Hours |

| Temperature | -40°C |

TEST PERFORMANCE

| Functional Test | Performed by laboratory during and at the end of test. |

| Visual Test | Performed by laboratory during and at the end of test. |

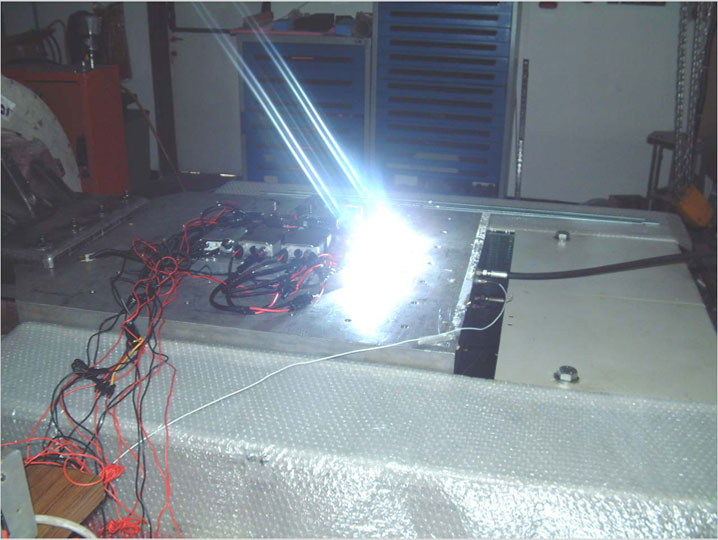

HID CONVERSION KIT LOCATED IN LOW TEMPERATURE CHAMBER

TEST RESULTS

In visual inspection at completion of the test, no external damage observed. Operational and visual tests have been conducted by the customer representatives during and at the end of the test.Pass O.K.

PRODUCT RESPONSE GRAPH

HIGH TEMPERATURE TESTUNIT UNDER TEST OVERVIEW

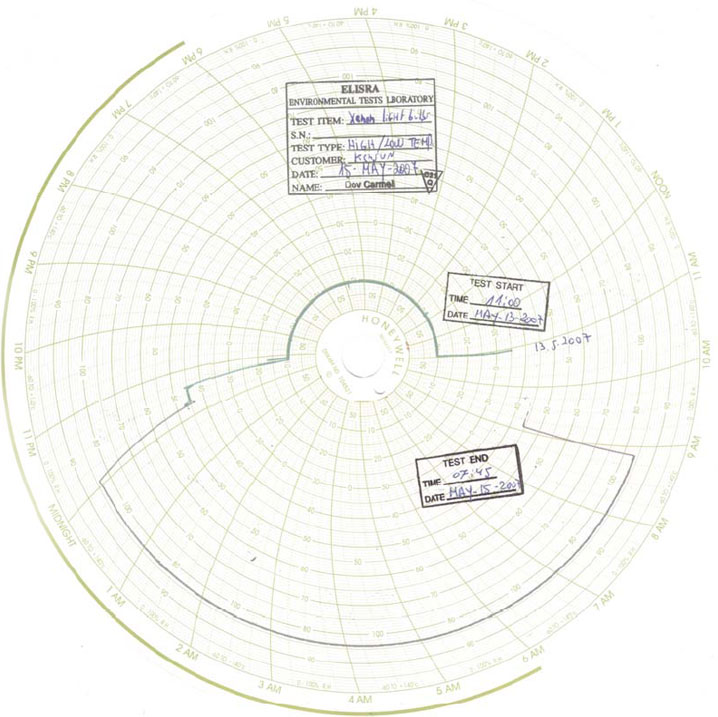

| Test Date | 14-15/5/07 |

| Customer Representative | Shmuel Etinger |

| Customer | KENSUN |

| Unit Name | HID CONVERSION KIT INCLUDES: H01 ELECTRONIC BALLAST 0902 ELECTRONIC BALLAST XENON LIGHTBULB |

| Item Quantity | 6 |

TECHNICAL SOURCE

. IEC-68-2 Test B : Dry heat.

3.3. TEST INSTRUMENTATION - TEMPERATURE CHAMBER

| No. | Manufacturer / Model | Calibration Expired Date |

| 1. | THERMOTRON Model F-35 | 31/10/2007 |

TEST PROCEDURE

EXCLUSIONS FROM THE TEST METHOD

HIGH TEMPERATURE TEST PROCEDURE DESCRIPTION

| Period | 16 Hours |

| Temperature | +105°C |

TEST PERFORMANCE

| Functional Test | Performed by laboratory during and at the end of test. |

| Visual Test | Performed by laboratory during and at the end of test. |

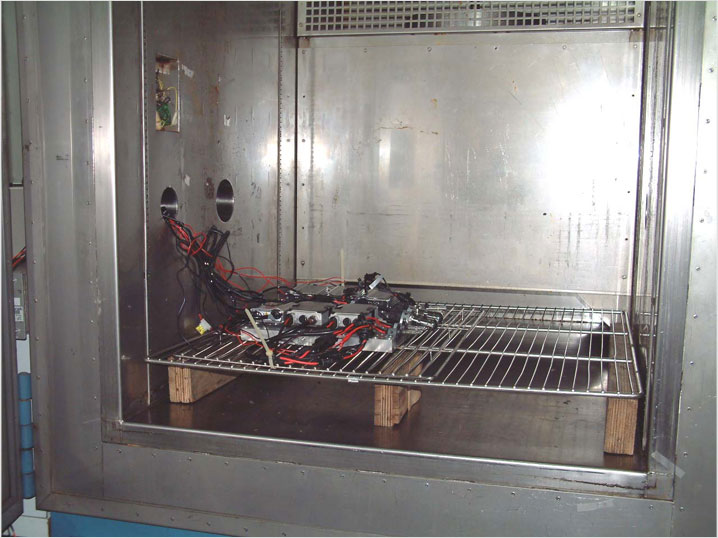

HID CONVERSION KIT LOCATED IN HIGH TEMPERATURE CHAMBER

. See pictures in paragraph 2.4.4

TEST RESULTSIn visual inspection at completion of the test, no external damage observed. Operational and visual tests have been conducted by the customer representatives during and at the end of the test.Pass O.K.

PRODUCT RESPONSE GRAPH

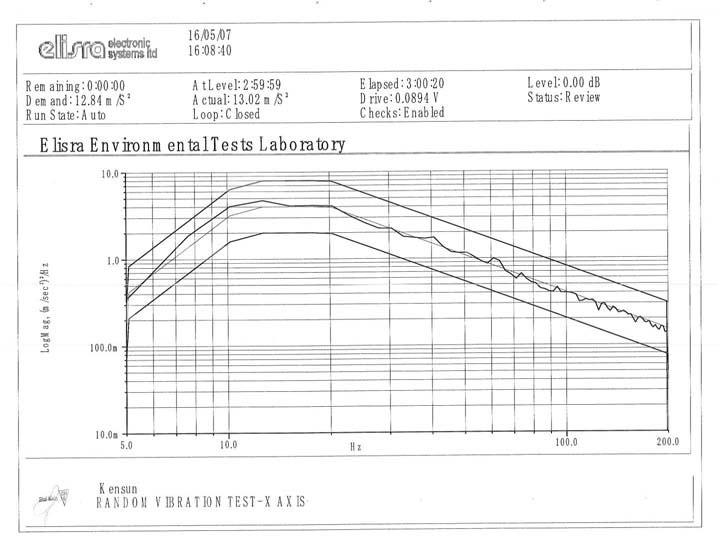

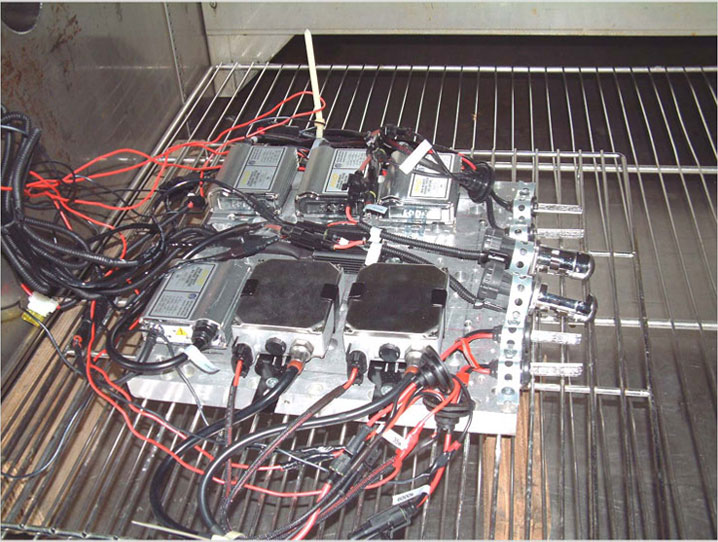

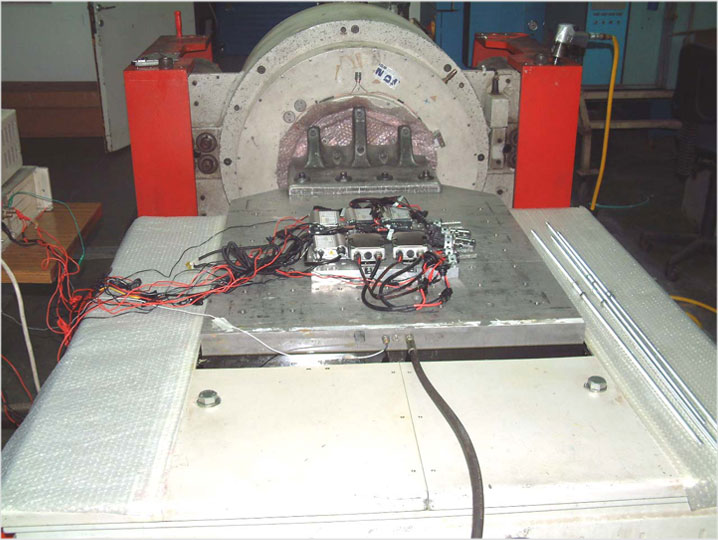

RANDOM VIBRATION TESTUNIT UNDER TEST OVERVIEW

| Test Date | 15,16/5/07 |

| Customer Representative | Shmuel Etinger |

| Customer | KENSUN |

| Unit Name | HID CONVERSION KIT INCLUDES: H01 ELECTRONIC BALLAST 0902 ELECTRONIC BALLAST XENON LIGHTBULB |

| Item Quantity | 6 |

TECHNICAL SOURCE

. BMW GROUP ELECTRICAL/ELECTRONIC ASSEMBLIES IN MOTOR VEHICLES GENERAL INFORMATION. GS 95003-1 MARCH/2000. SUPERSEDESRES 62.60013 PART 1, ISSUE 06.97.

. INSTALLATION AREA B1 - ENGINE COMPARTMENT ATTACHED TO BODY

TEST INSTRUMENTATION

| Instrumentation Name | Manufacturer / Model | Calibration Expired Date |

| Electrodynamics Vibration System | L.D.S – model: V-850 | N.C.R |

| Vibration Control System | D.P Model DP-550 | 30/04/2008 |

| Control Accelerometer | Endevco Model 224C. | 30/04/2008 |

TEST PROCEDURE4.4.2. VIBRATION TEST PROCEDURE DESCRIPTION

EXCLUSIONS FROM THE TEST METHOD

Not applicable.

ENV_REPORT_RENDOM_PROCEDURE_ITEM_TITLE

| Item Position | The test item was rigidly attached to vibration exciter |

| Vibration Axes | 3 (X, Y, Z). |

| Frequency Range | 5-200 Hz. |

| Vibration Time in Each Axis | 3 hours |

| Vibration Level | 1.28 g rms |

TEST PERFORMANCE

| Functional Test | Performed by laboratory during and at the end of test. |

| Visual Test | Performed by laboratory during and at the end of test. |

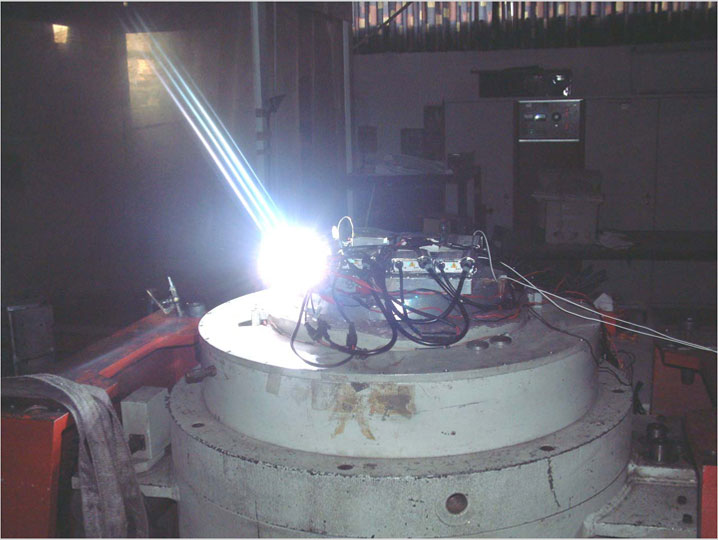

HID CONVERSION KIT MOUNTED ON ELECTRODYNAMICS SHAKER

TEST RESULTS

In visual inspection at completion of the test, no external damage observed. Operational and visual tests have been conducted by the customer representatives during and at the end of the test. Pass O.K.

PRODUCT RESPONSE GRAPHS